Prefabricated Formworks

Prefabricated Formworks

Roof Scissor Formwork

Roof scissor formwork enables the pre-stressed reinforced concrete scissor beam, which is the roof-bearing element of prefabricated buildings, to be manufactured at the desired angle and length. The roof scissor mold, which has an opening and closing feature is durable due to the material it is produced from. The roof scissor formwork ensures that the roof has the desired slope. Our new generation roof truss molds are easy-to-use, long-lasting, fireproof, durable, not affected by water and moisture, and resistant to sunlight and heat.

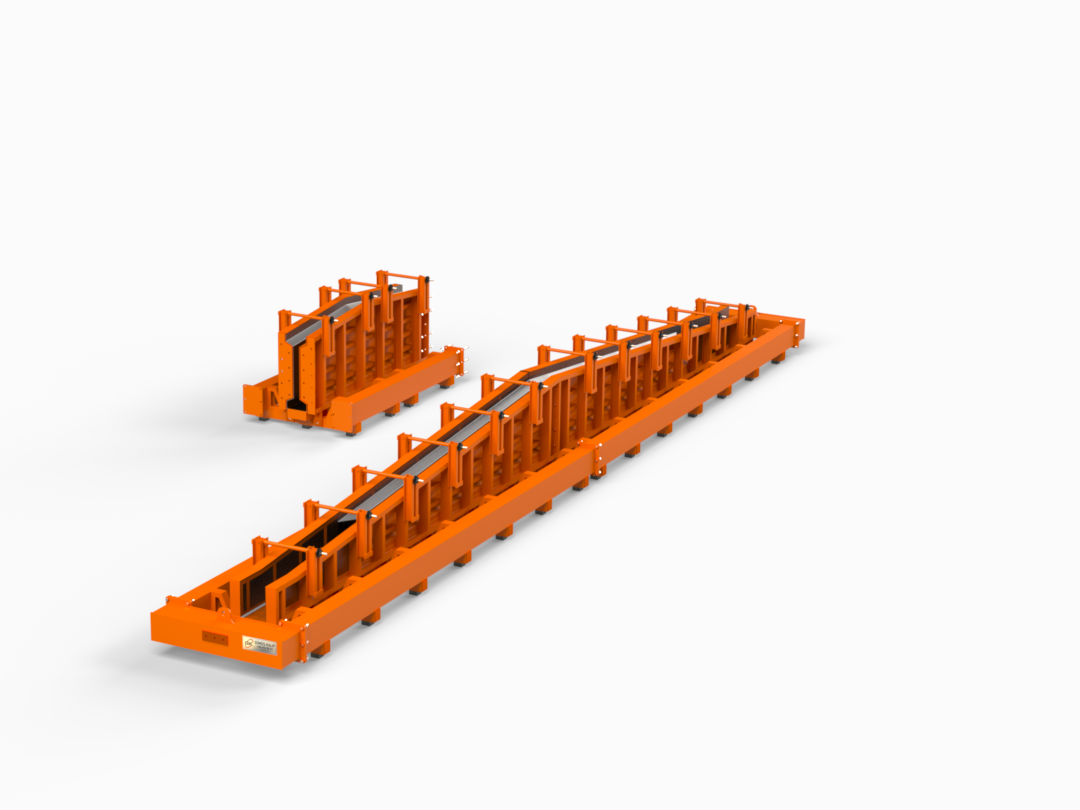

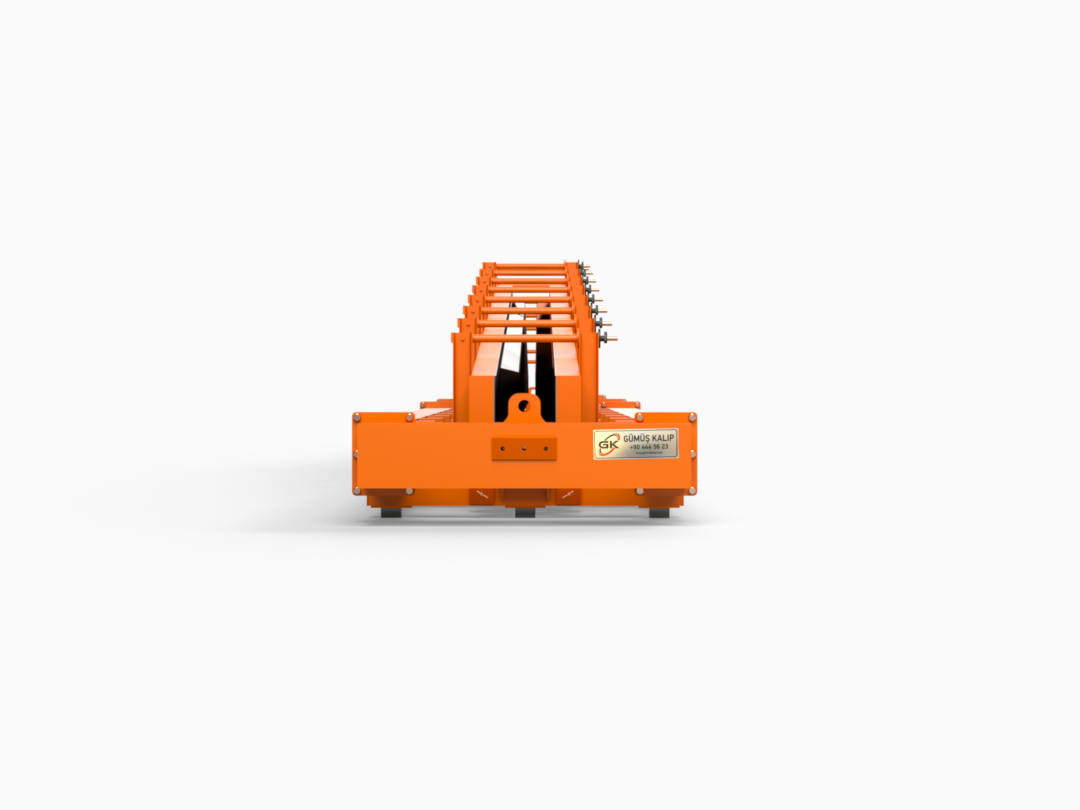

Prefabricated Column Formwork

Columns, which are vertical load-bearing elements of reinforced concrete prefabricated structures, are produced with Gümüş column formwork systems. The prefabricated column formwork, which is designed according to the column thickness and length by taking project measurements, also includes beam and roof connection sections. Prefabricated column molds, which are durable and long-lasting due to the material used in their production, provide ease of installation and transportation as they have assembly/disassembly feature. Column molds have a hinge and collapsible connection feature. Optionally, prefabricated column molds that work by narrowing and expanding the sheet metal can also be produced.

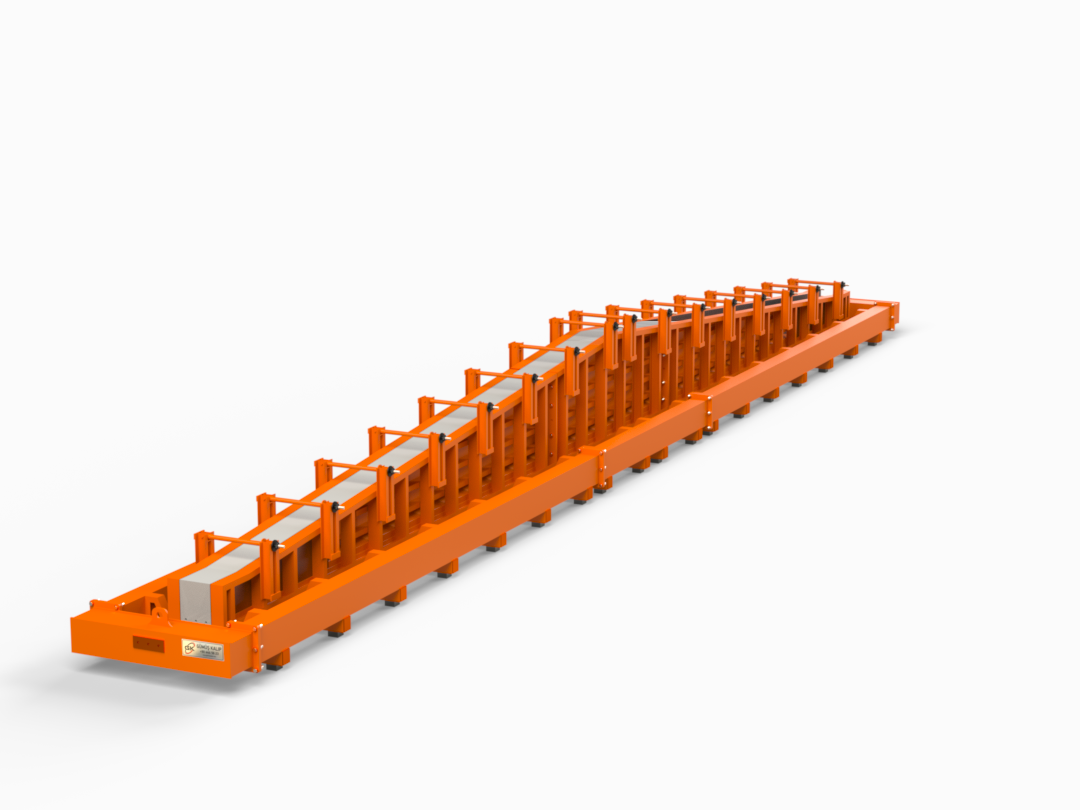

Beam Formwork

Prestressed reinforced concrete beams, which are horizontal carrier elements of prefabricated structures, are produced with beam mould. Thickness and length measurements of the beam formwork are taken from the project. Prefabricated beam molds, which are durable and long-lasting due to the material used in their production, have opening and closing features. Pre-stressing calculations are taken during mold production.

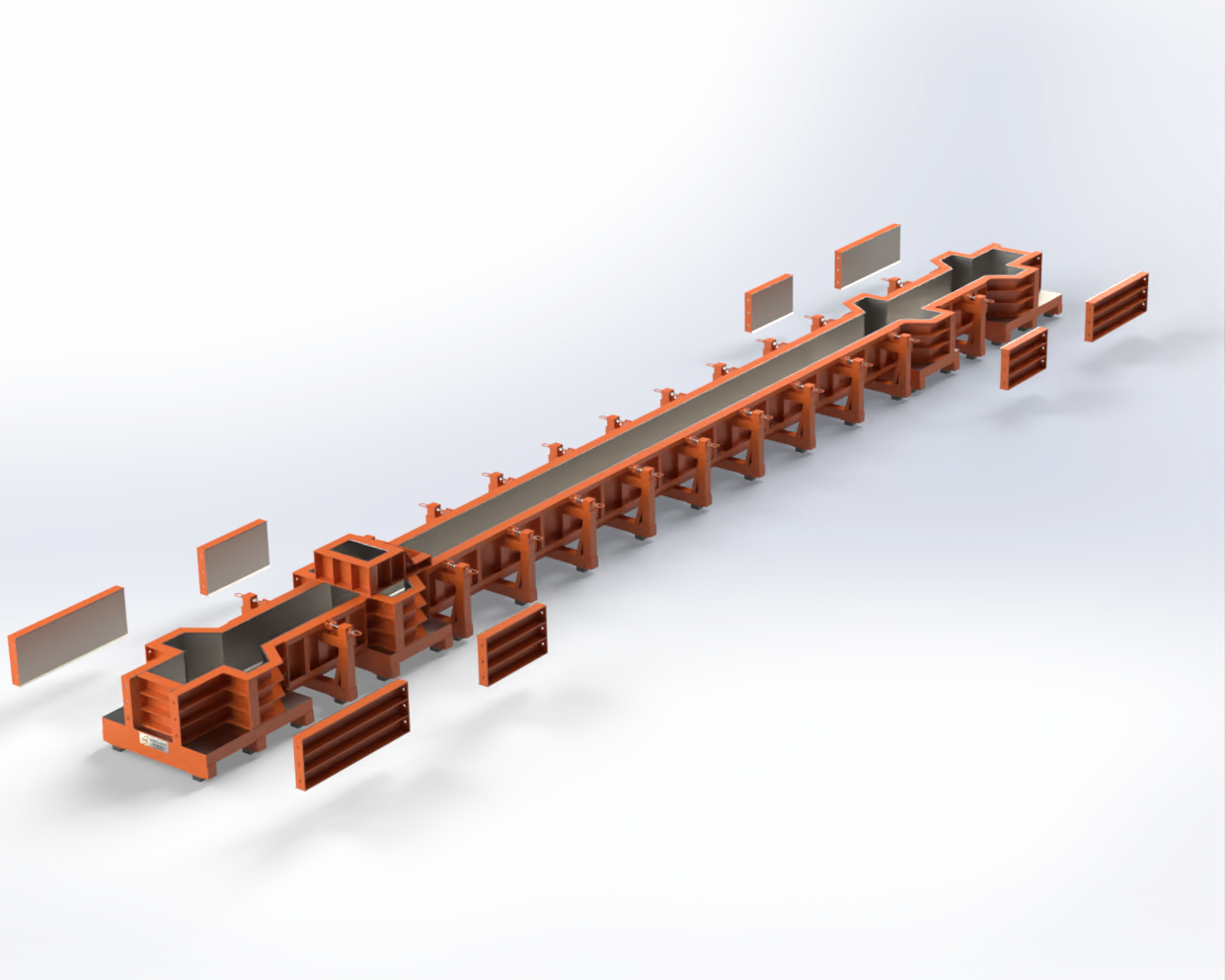

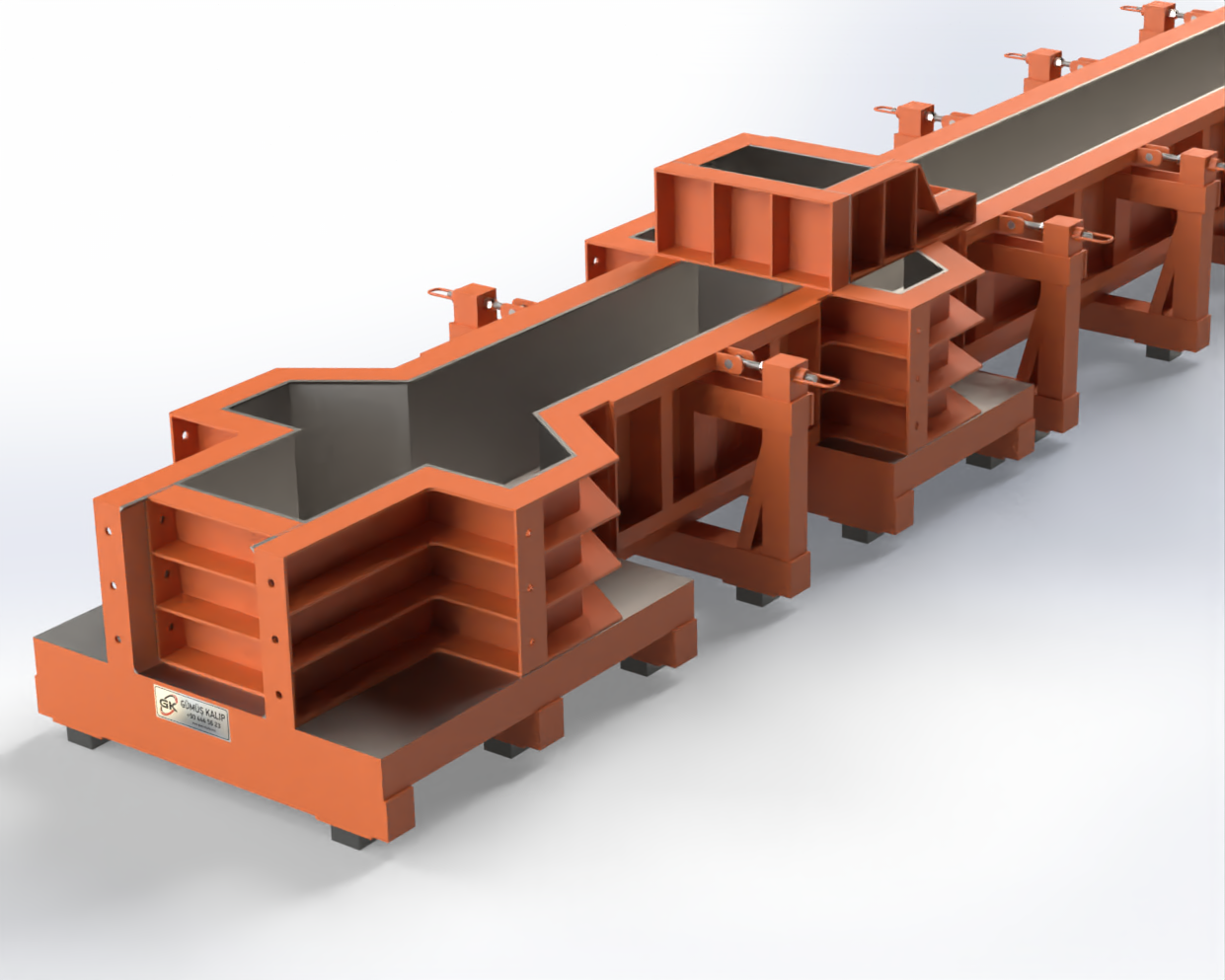

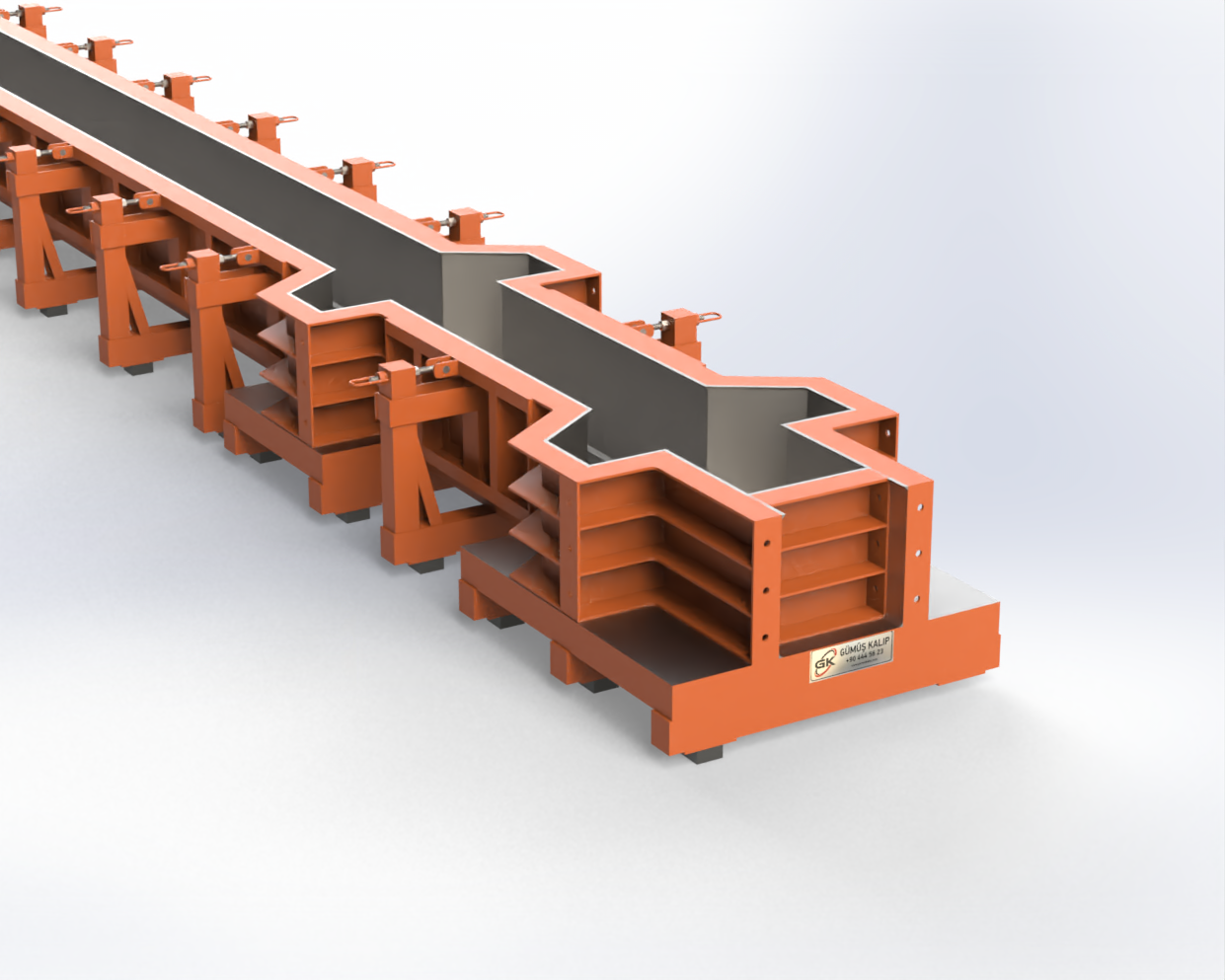

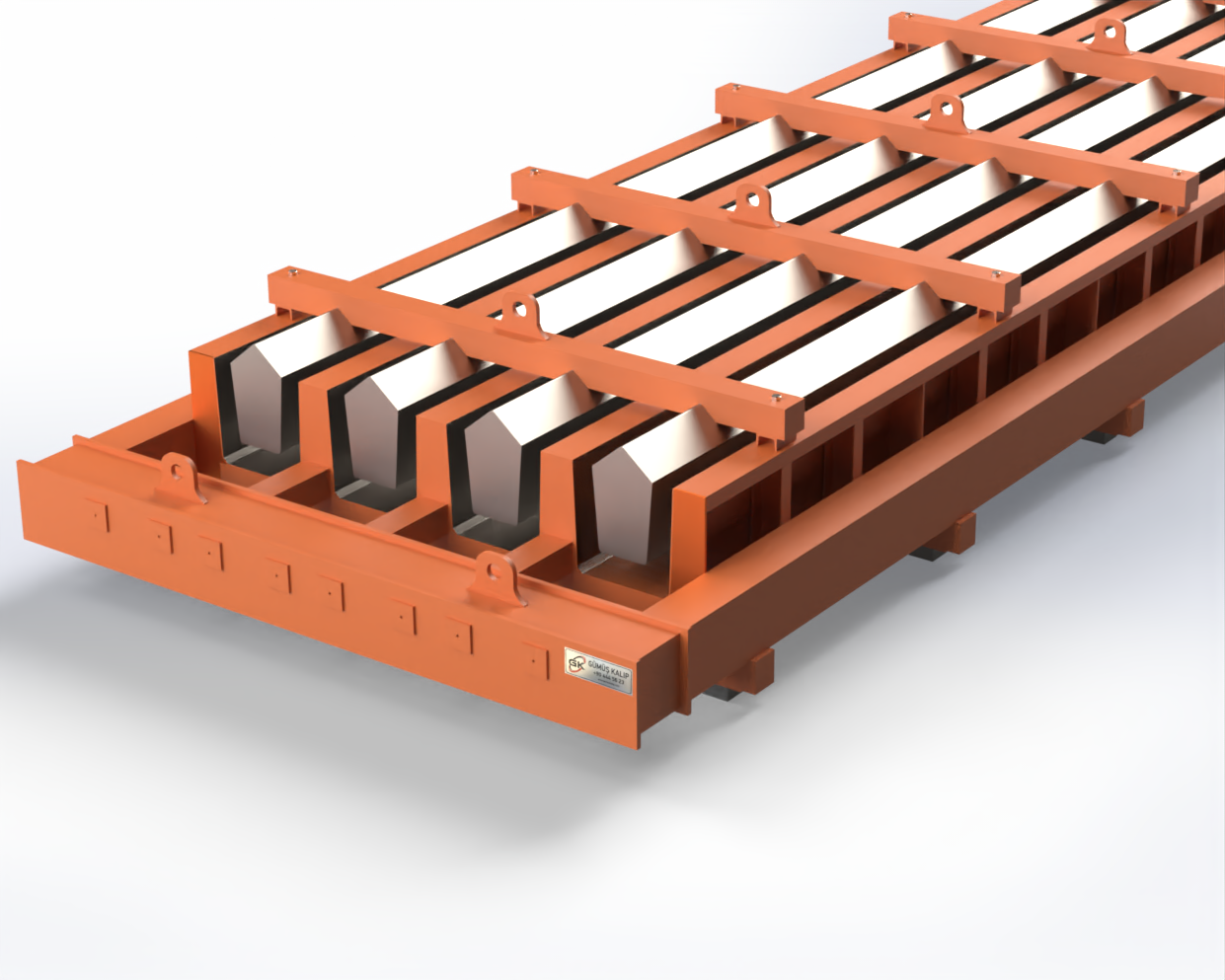

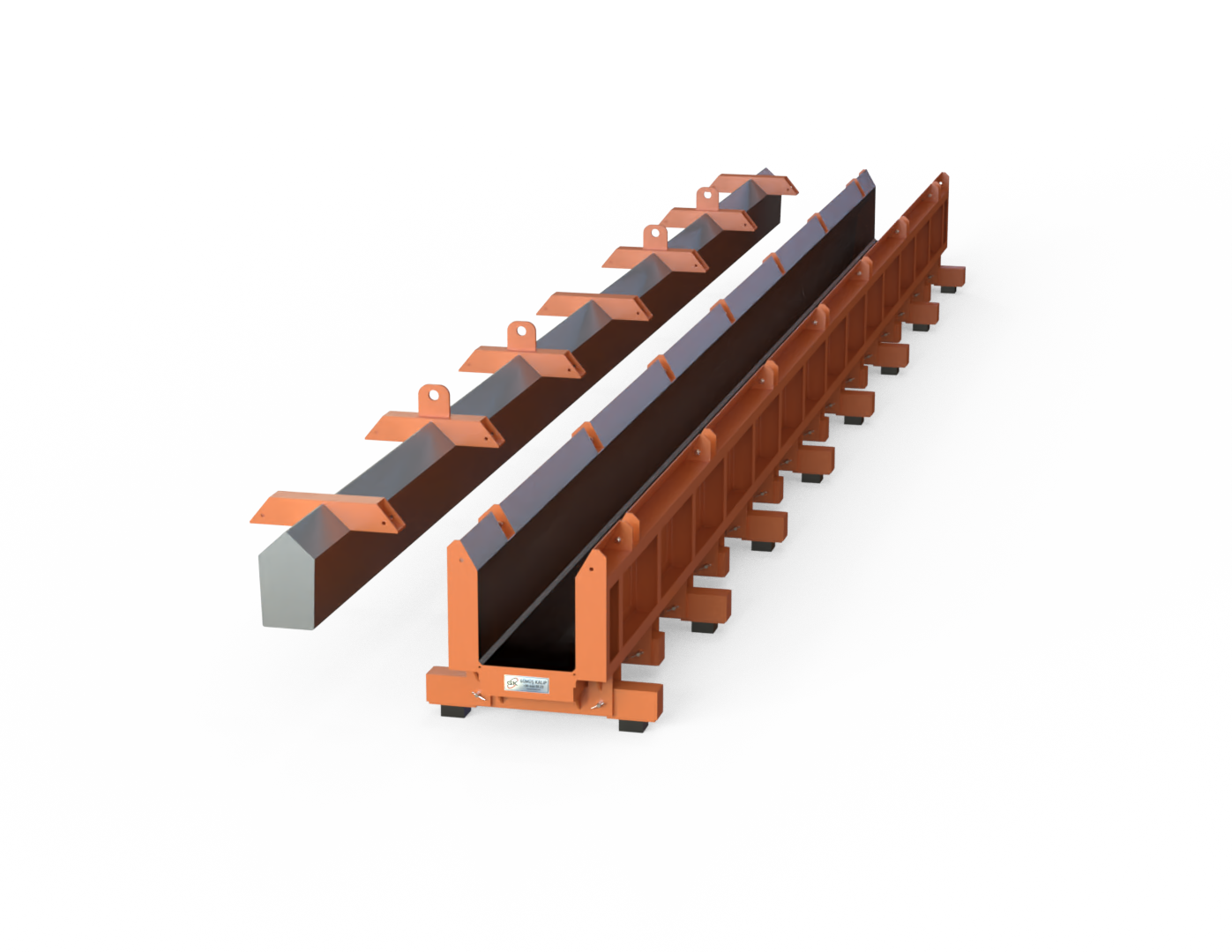

Purlin Formwork

Purlin formwork is used in the production of prestressed purlin beams, which transfer the roof load of reinforced concrete prefabricated structures to the bearing elements and to which the roof coverings are fixed. These molds, whose length and thickness vary depending on the prefabricated structure produced, consist of 8 or 10 mold systems depending on preference. These moulds produced for multiple manufacturing, allow easy separation of the beam from the concrete with their slope. Pre-stressing calculations are taken during mold production. The mold material is durable and long-lasting.

Socket Formwork

Sockets, which are foundation system elements used in reinforced concrete prefabricated structures; It is manufactured by pouring concrete into the socket mold. Socket molds, which are manufactured according to the basic dimensions of the structure to be built, are divided into internal and external molds. While the concrete is setting, the molds are fixed at their upper parts with fasteners. In this way, it is ensured that the molds are square. Socket thickness is determined according to the project. Our new generation socket molds are easy to use, long-lasting, fireproof, durable and resistant to water and moisture. It is a material that is unaffected and resistant to sunlight and heat.